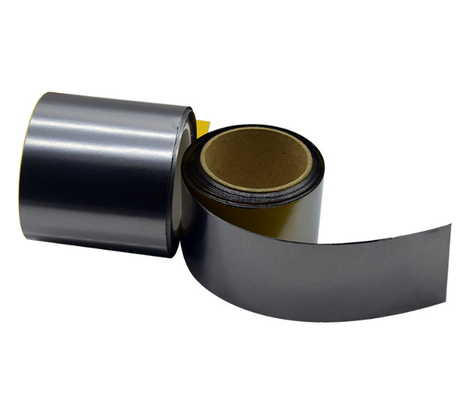

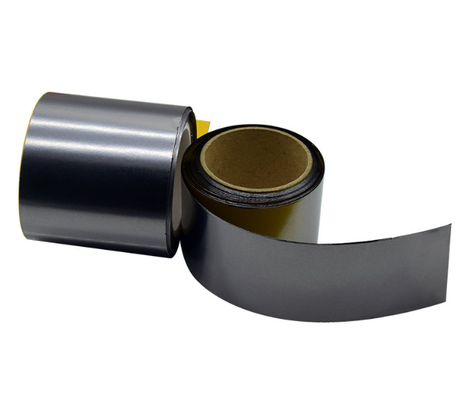

Electromagnetic Heat Dissipation Metalized Polyester Film

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Graphene | Colour | Black |

|---|---|---|---|

| Length | 100-2000mm,Customized | Width | 50-1000mm,Customized |

| Thickness | 50μm - 200μm | Feature | Waterproof, Moisture Proof |

| High Light | Heat Dissipation metalized polyester film,Electromagnetic metalized polyester film,Electromagnetic heat dissipation film |

||

New Electromagnetic Shielding Heat Dissipation Copper-Based Graphene Static Plastic Film

Product introduction:

As electronic products such as mobile phones become thinner, have longer battery life, and develop towards 5G communication, their requirements for heat dissipation performance are also getting higher and higher. Heat dissipation components in electronic products such as mobile phones are also attracting more and more attention.

At present, the heat dissipation films used in mobile phones mainly include natural graphite heat dissipation films and polyimide artificial graphite films. Among them, the thickness of natural graphite heat dissipation film products is difficult to reduce and the thermal conductivity is low, and the use is increasingly limited. "Polyimide artificial graphite heat dissipation film is widely used in the market, and its thermal conductivity is generally 600~1500W/(m·K), the highest quality products can reach about 1950W/(m·K), and the thinnest products It can be as thin as 10 microns. However, the cost of this product is relatively high, the cost per square meter is at least 400 yuan, and the yield of the product during processing is not high, and the edge of the film is easy to drop powder during the die-cutting process. Expensive." Is there a better heat-dissipating film material that can solve the above problems? The answer is graphene films.

Graphene is a variant (form) of a single layer of carbon atoms arranged in a hexagonal lattice. It is the basic structural element of many other isoforms of carbon, such as graphite, diamond, carbon, carbon nanotubes and fullerenes. Graphene has many unusual properties, it conducts heat and electricity efficiently, it is also very conductive, and it is almost transparent.

With the development of electronic devices and products to the field of high integration and high computing, the power dissipation is multiplied, and heat dissipation has become an urgent problem to be solved. Most of the traditional thermal conductive materials are metals (Ag, Cu, Al, etc.), metal oxides (Fe2O3, BeO, Al2O3, etc.), and other non-metallic materials (graphite, carbon black, AlN, etc.). For a long time, in the fields of heat dissipation of electronic devices and products, traditional heat dissipation materials such as copper and aluminum have been widely used; the graphene material emerging in recent years, with its excellent thermal conductivity, rapid heat dissipation (convection with air) and It is considered to be a very competitive heat dissipation material due to its light weight and flexibility.

Graphene heat dissipation principle

In thermodynamics, the heat dissipation of graphene heat dissipation film includes conduction, convection and radiation, as shown in Figure 1. For example, the direct contact between the CPU heat sink base and the CPU to take away heat is thermal conduction; the common cooling fan drives the gas flow, that is, thermal convection; thermal radiation refers to relying on ray radiation to transfer heat. Under normal circumstances (below 400 degrees Celsius), the heat dissipation system mainly relies on heat conduction and heat convection. The heat conduction is mainly related to the thermal conductivity and heat capacity of the radiator material, and the heat convection is mainly related to the heat dissipation area of the radiator.

Features of synthetic graphite sheet:

* Excellent thermal conductivity: up to 1950 W/m•K

(2 to 5 times as high as copper, 3 to 8 time as high as aluminum)

* Lightweight: Specific gravity: 1.0 to 2.1 g/cm3

* Flexible and easy to be cut. (Withstands repeated bending)

* Low thermal resistance

* Low heat resistance with flexible graphite sheet

* Low repulsion and easy to keep the product's shape after attaching

* RoHS, REACH compliant

![]()